Rolling bearing design examples

On this page, we present various examples of encapsulating designs for rolling bearings. You will find out which designs are suitable for different applications, which material combinations are used and which design measures contribute to extending the service life.

From simple housings to complex, high-precision bearing arrangements - discover innovative solutions for the safe and efficient integration of rolling bearings in technical systems.

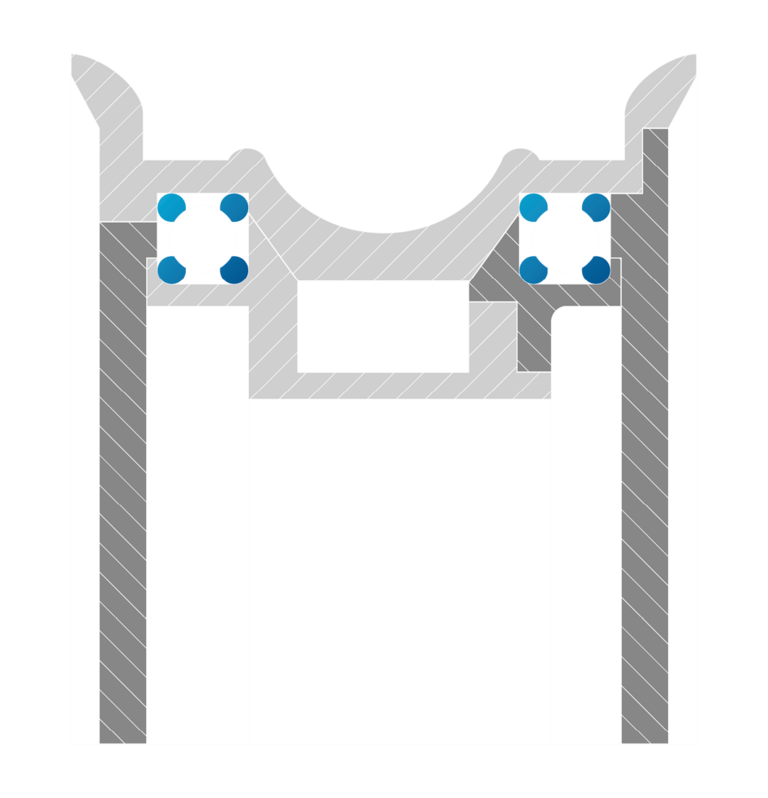

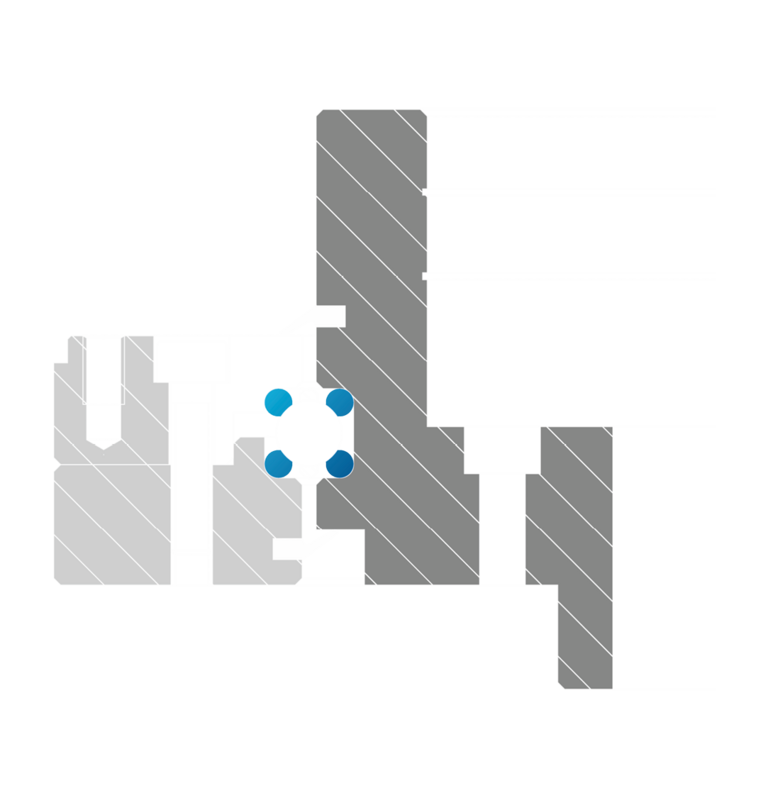

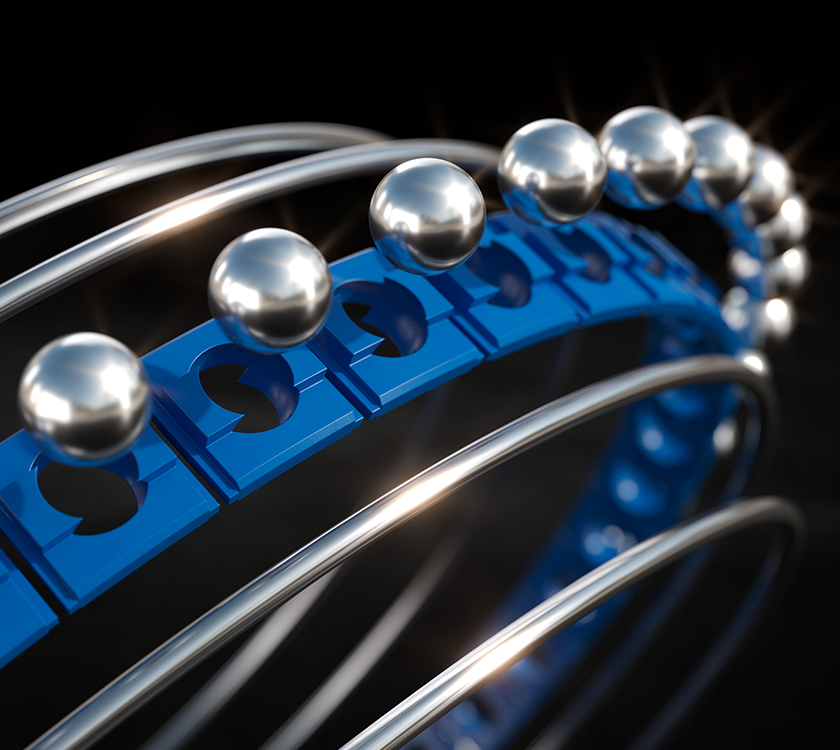

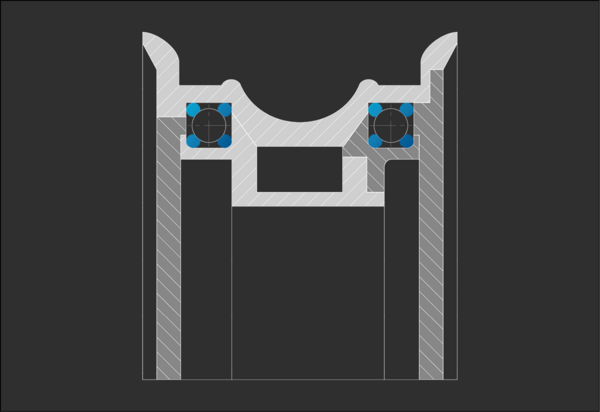

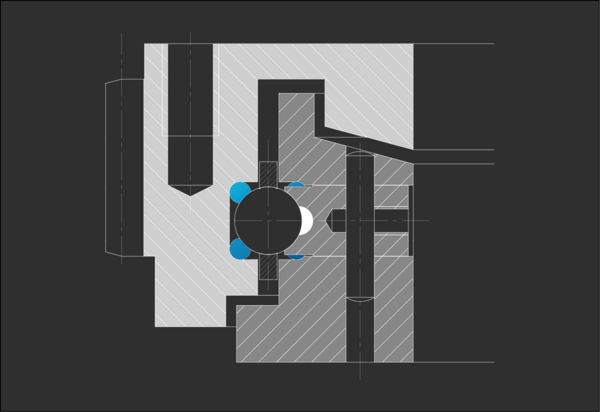

Construction 1

2-row angular contact ball bearing

The main bearing of the computer tomograph plays a decisive role in precise imaging. Even at high speeds, it must run quietly and with low vibration, while ensuring precise radial and axial run-out. The Franke slewing ring impresses with extremely smooth running at speeds of up to 300 rpm.

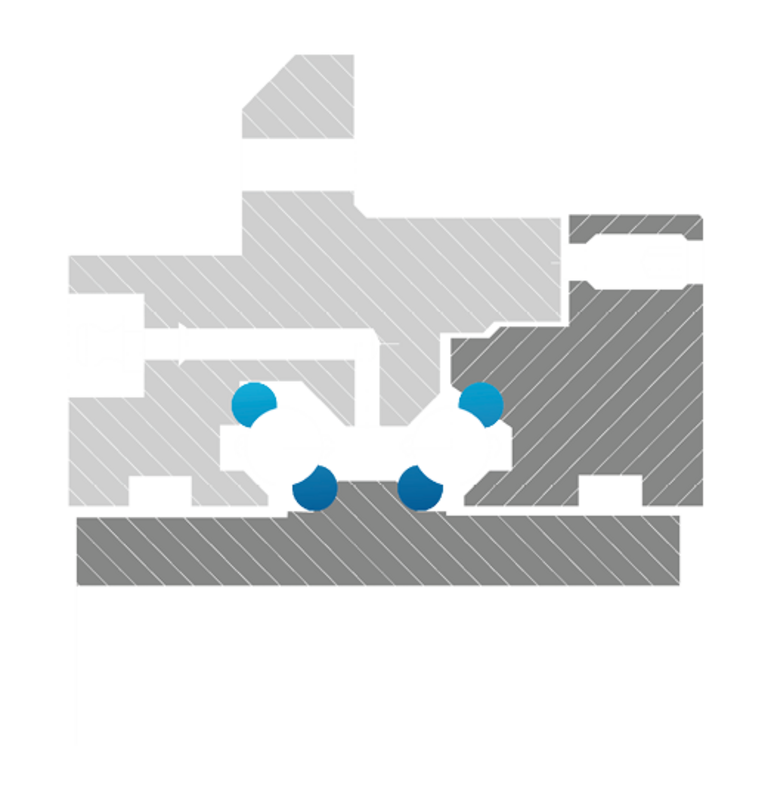

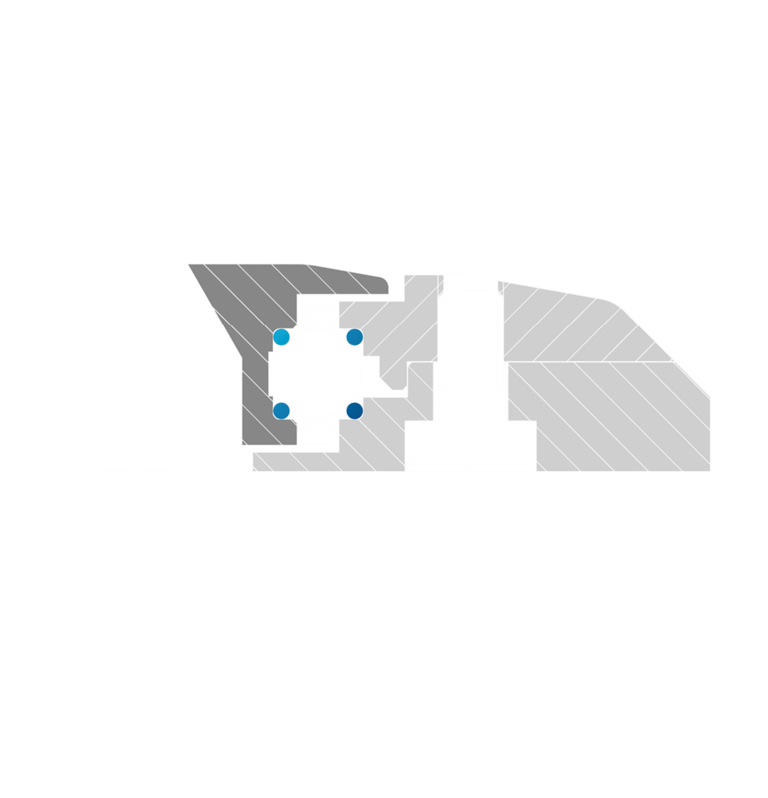

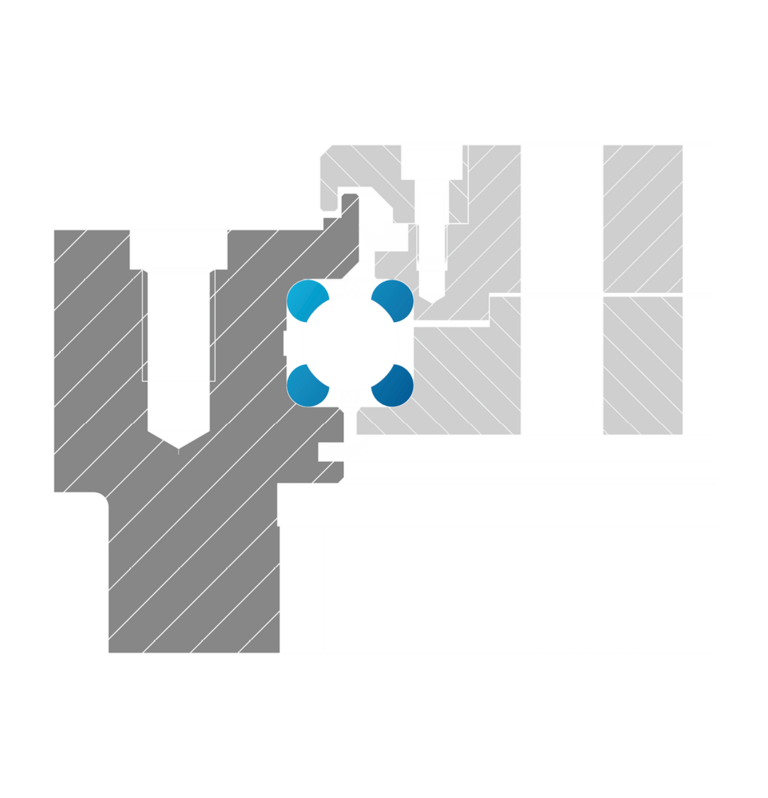

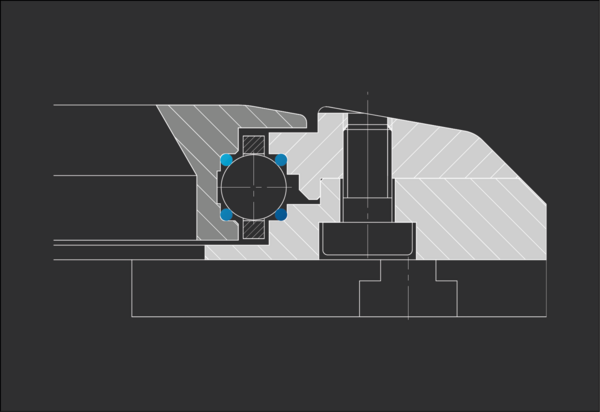

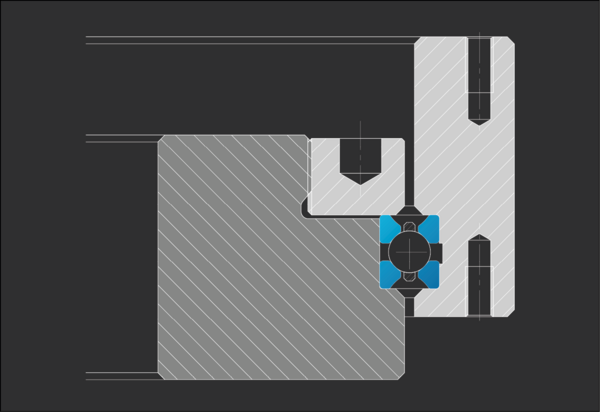

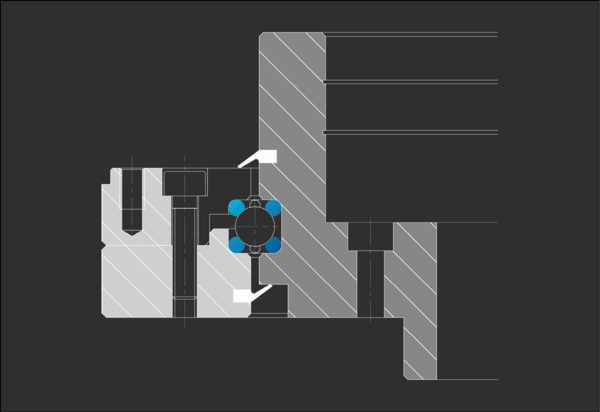

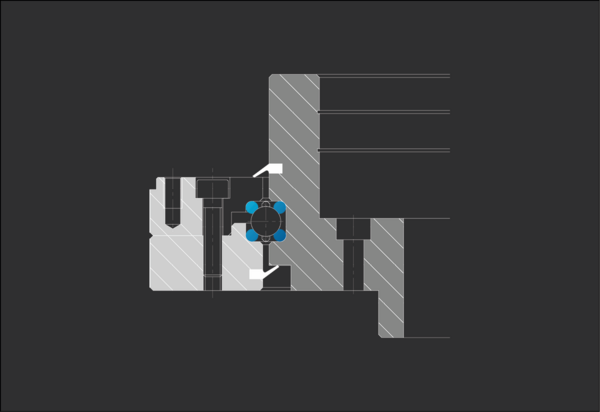

Construction 2

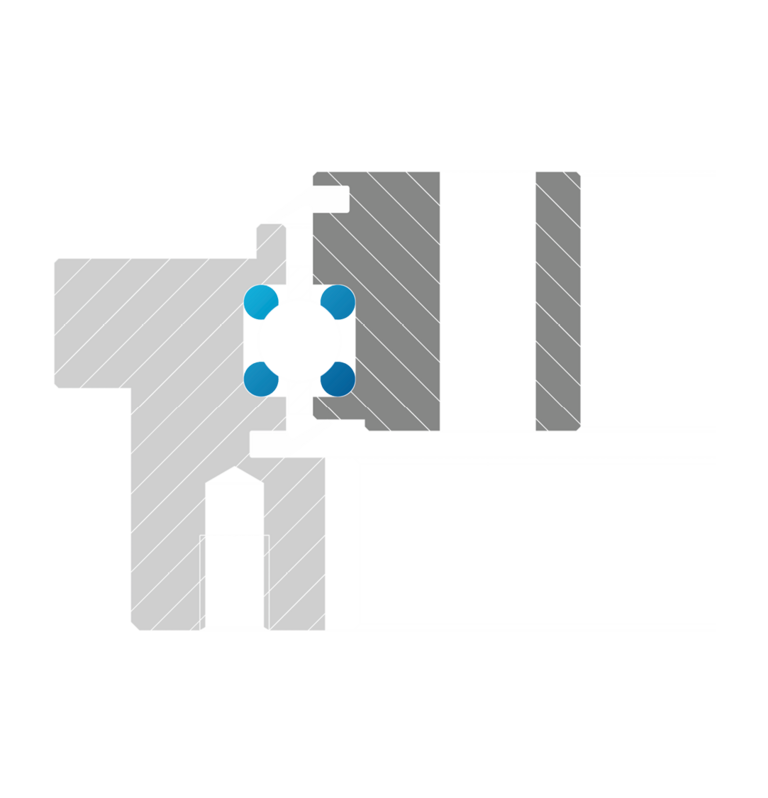

4-point ball bearing

The articulated robot is used as a service or mobile robot. With a dead weight of just 10 kg and a nominal load of 3 kg, it is made of lightweight CFRP materials that offer high rigidity with minimal weight.

Wire race bearings are used for the movement axes, which combine high rigidity, low weight and a small installation space. Thanks to their compact design, they can be seamlessly integrated into the design of the robot. As the rolling bearing has no influence on the material of the enclosing structure, this can be freely selected.

The bearing is characterized by a high load capacity from all directions and ensures precise, low-friction movement of the robot joints.

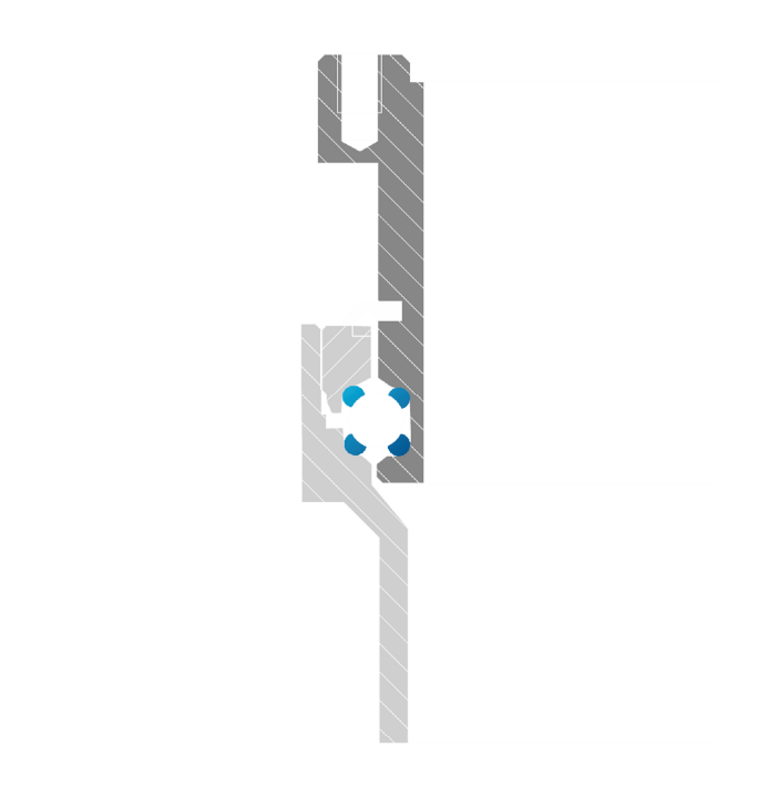

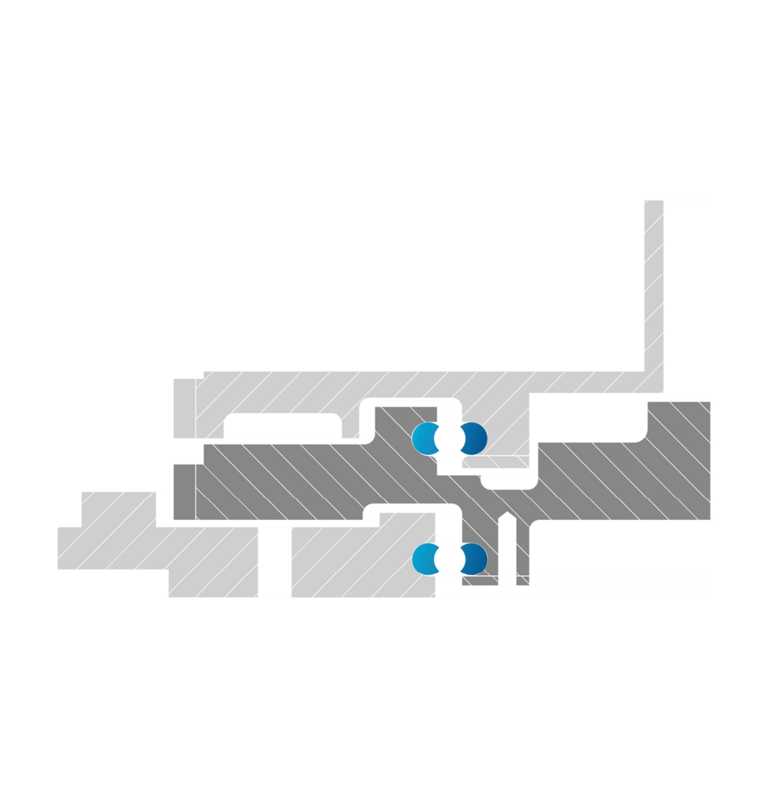

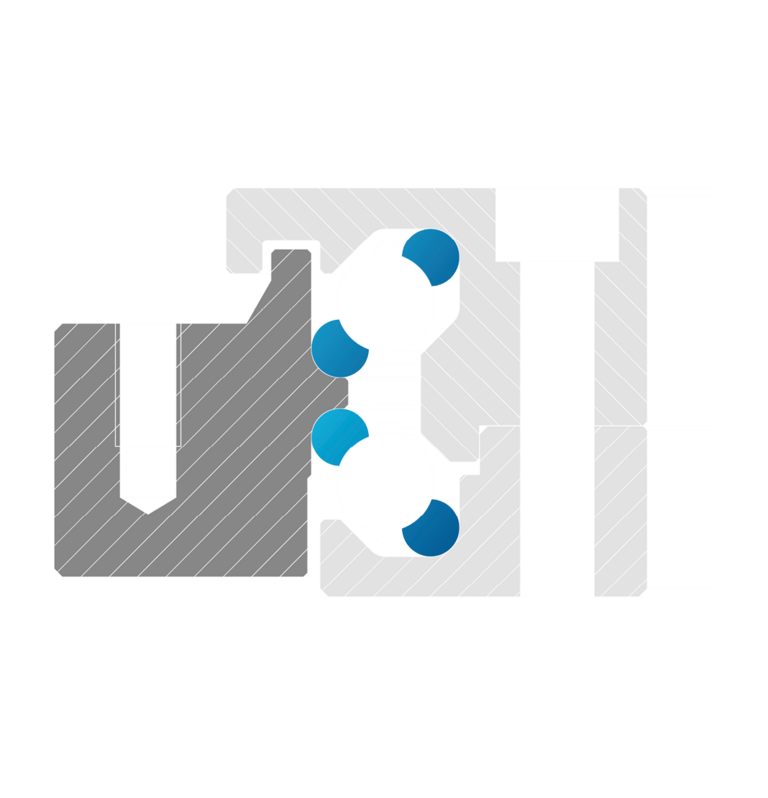

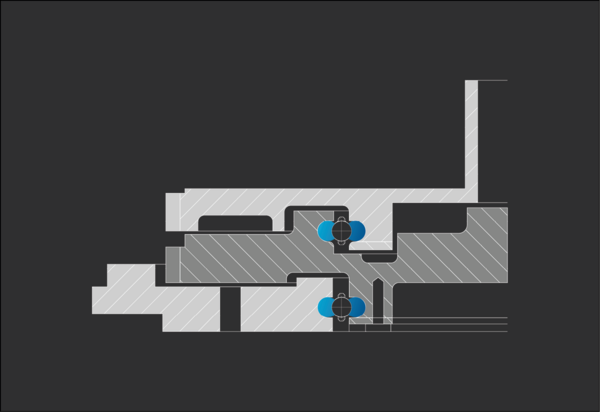

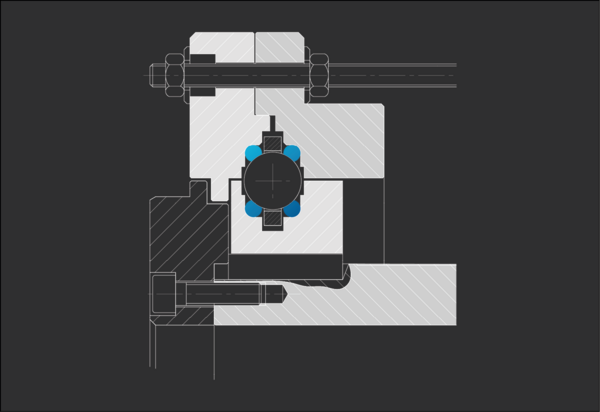

Construction 3

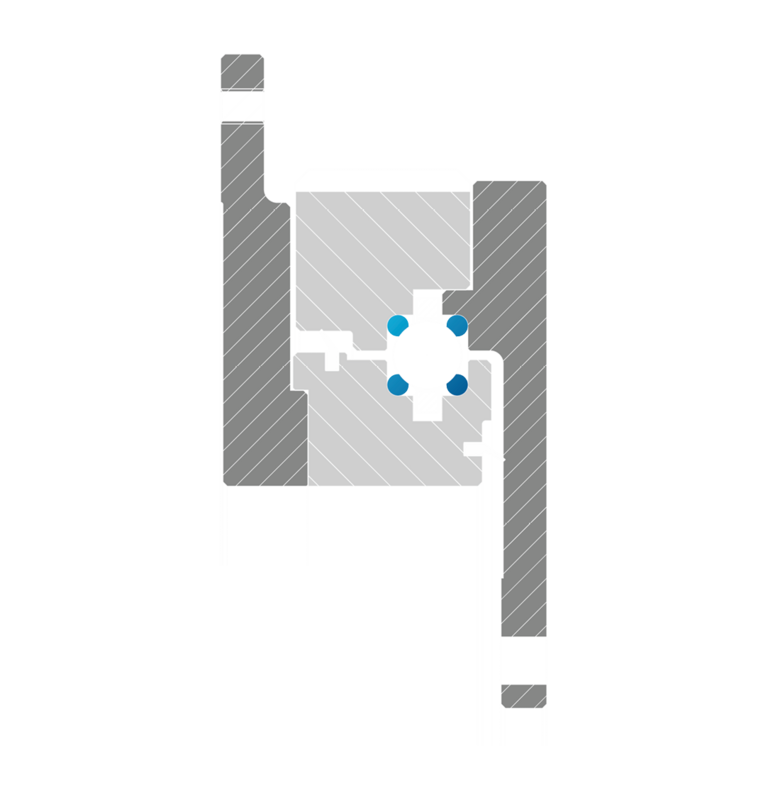

Thin section bearing

Franke thin-section bearings of type LSA impress with their particularly smooth running, extremely compact installation space and simple installation - and all at an attractive price.

They consist of an inner and outer race with a hardened, profiled raceway and a plastic cage with retained balls. Thanks to the tried-and-tested 4-point system, the rolling elements are in contact with two points on each race, which ensures high running accuracy and load capacity.

A particular advantage: The split races allow the diameter to be adjusted elastically during installation, which makes assembly even easier.

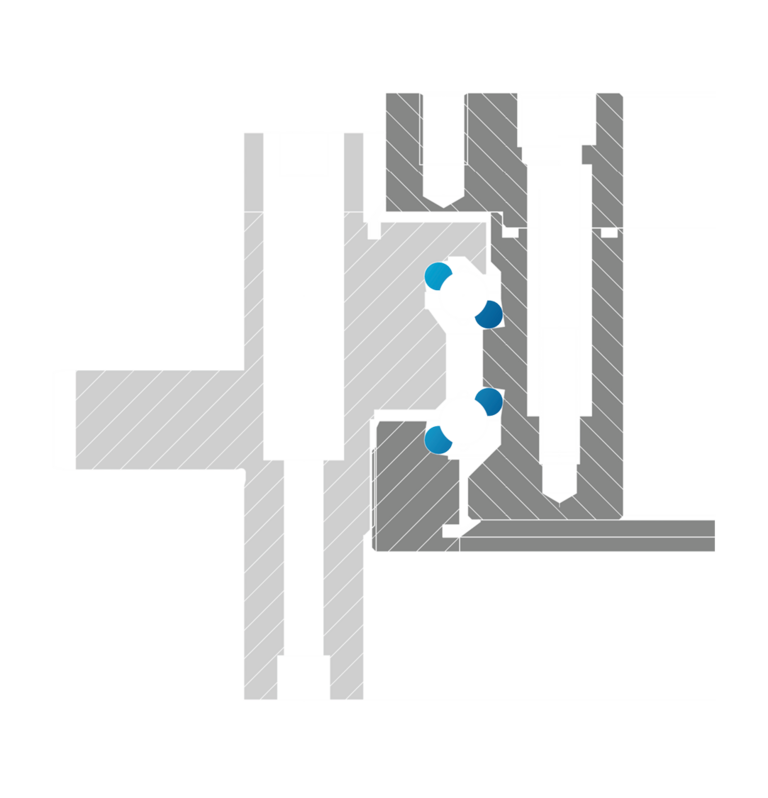

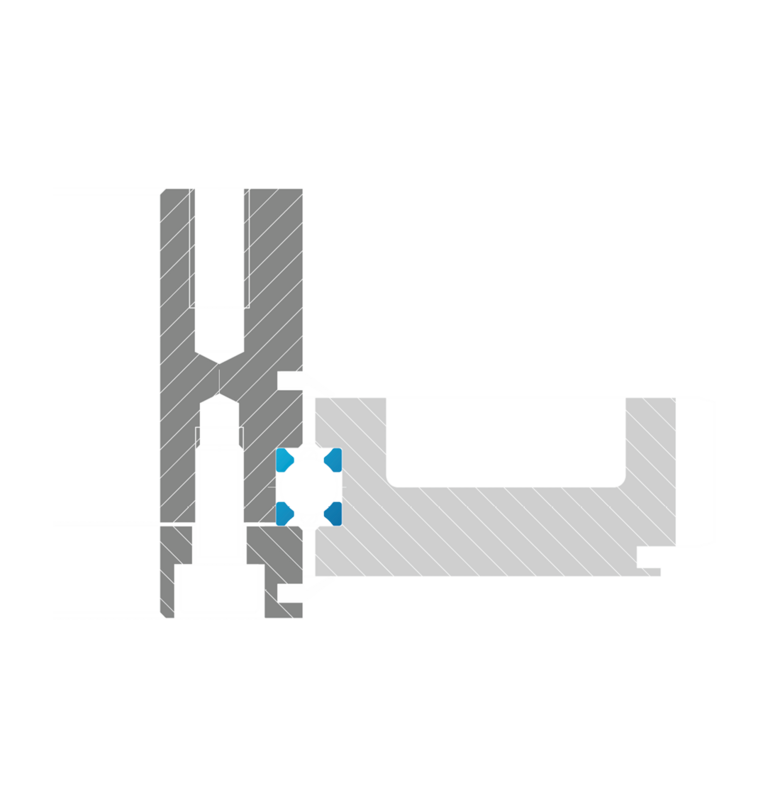

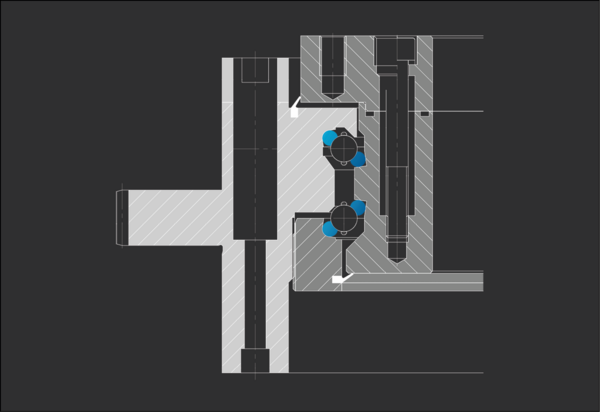

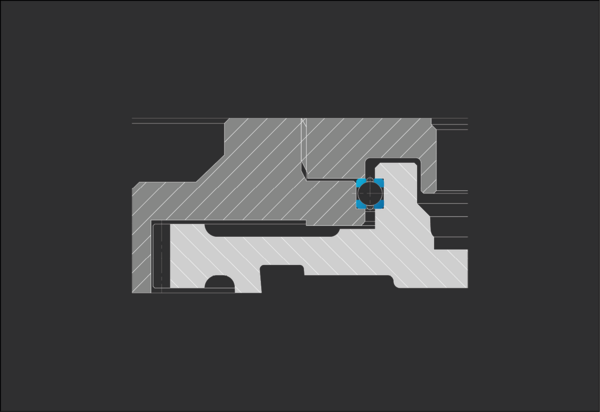

Construction 4

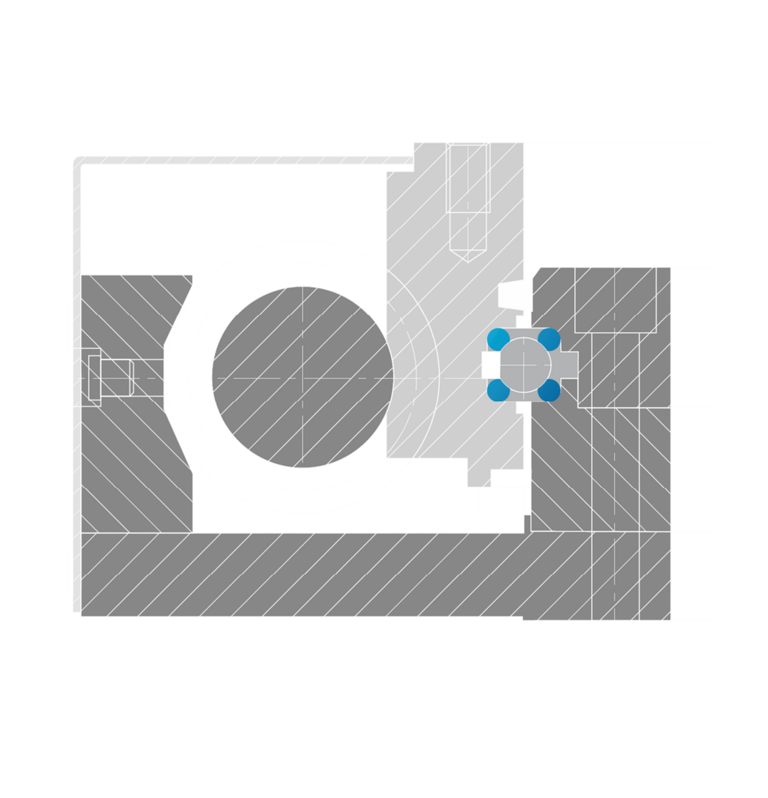

2-row 4-point ball bearing

A concept vehicle is equipped with one direct drive per wheel. This requires a compact, high-performance bearing that offers a high load capacity despite taking up minimal space. The maximum speed is 1,000 rpm, and due to the proximity to the direct drive, the balls of the rolling bearing must be non-magnetic. The solution is a custom-made bearing with ceramic balls that has been specially developed to meet these requirements. The rolling bearing is integrated directly into the customer's design and can absorb forces from all directions, including tilting moments. The installation space was optimized in close cooperation and the assembly of the prototype bearing is carried out jointly at Franke.

Construction 5

4-point ball bearing

A specially adapted wire roller bearing is used for the low-friction and precise guidance of wooden parts to the milling head. This enables smooth and precise movement of the workpieces with minimal breakaway and friction torque. Thanks to the compact design of the complete system, the installation space remains particularly small, while the high precision and smooth running of the bearing ensure optimum processing quality.

Construction 6

2-row 2-ring ball bearing

Specially developed thin-section bearings in a special design are used in medical centrifuges for blood samples. Each unit is equipped with two backlash-free bearings that ensure maximum precision and smooth running. The bearing races are chemically nickel-plated and, in combination with stainless steel balls, are particularly corrosion-resistant - ideal for long-term use in sensitive laboratory environments. With a rotational resistance of less than 0.3 Nm, they enable smooth and efficient rotation, which ensures accurate analysis of blood samples.

Construction 7

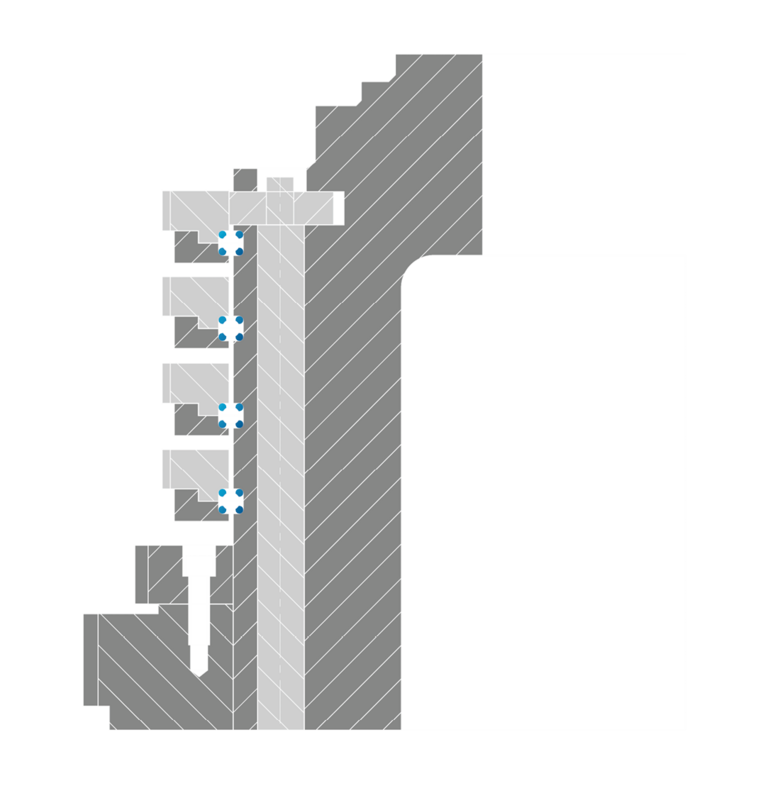

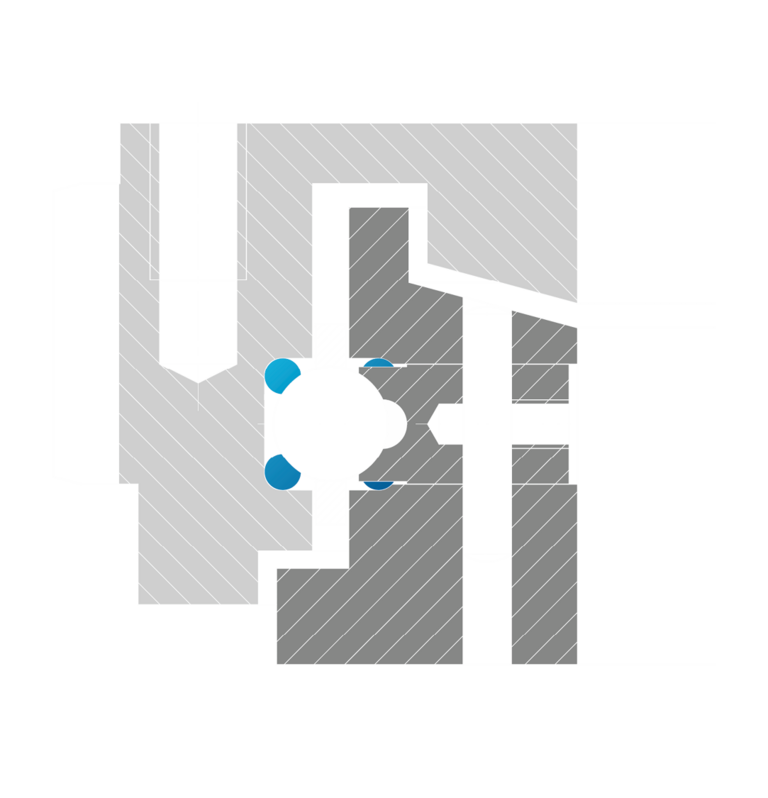

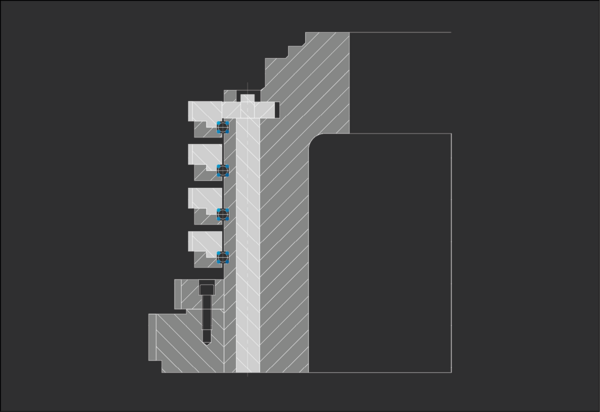

2-row angular contact ball bearing

Our specially developed rolling bearing for machine chucks in laser tube cutting machines enables maximum flexibility and independence from the chuck manufacturer. Thanks to the adaptable assembly design, it can be individually integrated into various systems. The preloaded bearing ensures maximum rigidity and accuracy, while the synchronized movement of the clamping jaws is precisely controlled via the bearing. Thanks to minimal tolerances on the mounting eyes of both outer rings, precise assembly and reliable function are ensured. An additional advantage: the running-in process is already carried out at Franke, saving valuable time during commissioning. We also offer a short delivery time and a target price that is on a par with standard bearings - an economical and high-performance solution for your application.bnahme eingespart wird. Zudem bieten wir eine kurze Lieferzeit und einen Zielpreis, der sich auf dem Niveau von Standardlagern bewegt – eine wirtschaftliche und leistungsstarke Lösung für Ihre Anwendung.

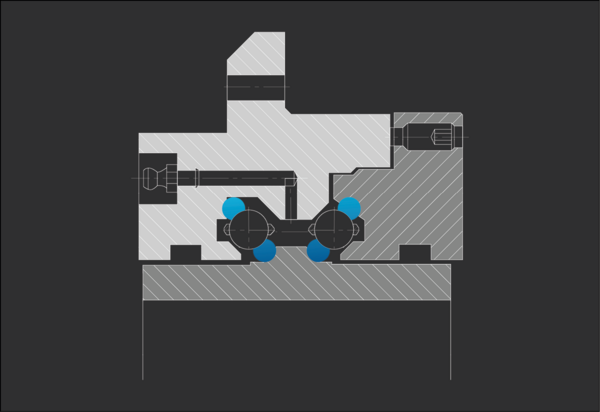

Construction 8

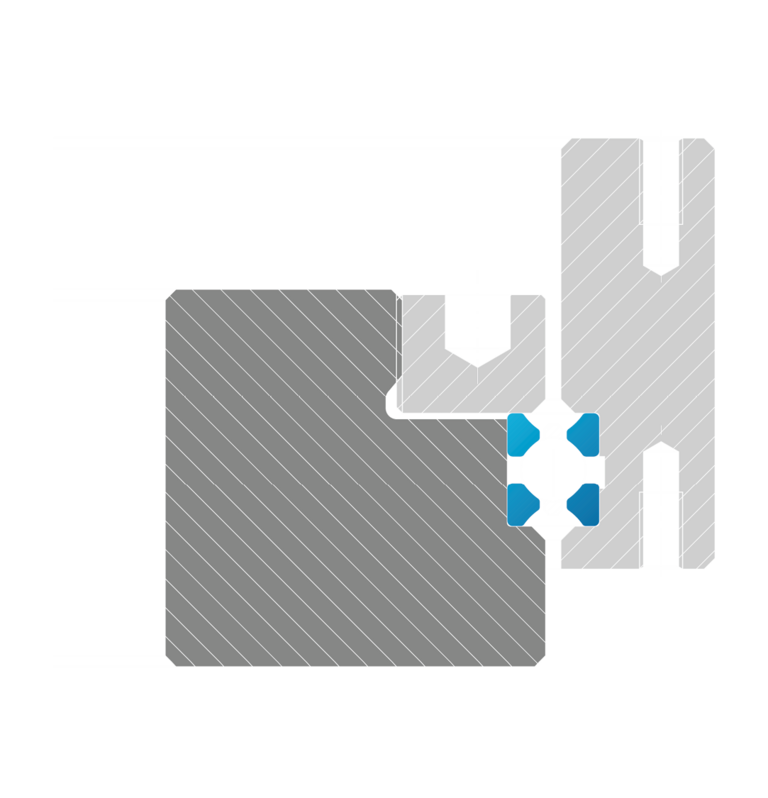

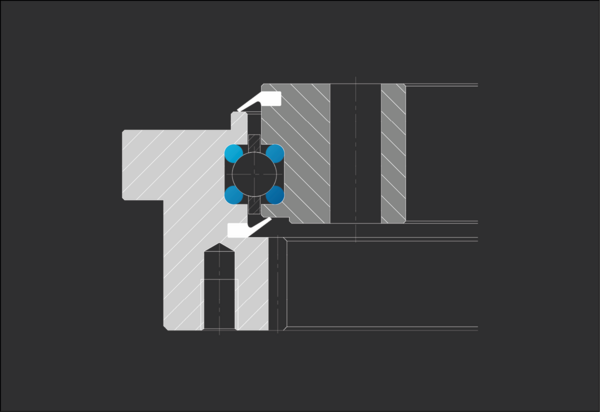

Multiple 4-point ball bearing

A specially developed drive system with integrated gear rims is used for maximum precision and stability during tube end machining. Due to limited space, the gear rims are integrated directly into the outer ring - a solution that guarantees maximum precision and rigidity.

The material combination of the surrounding components can be flexibly adapted to the specific requirements. We also supply the complete assembly as a customized unit - consisting of spiders, pinion and wire race bearing. We also offer customized bearing solutions for smaller quantities, which are optimally adapted to the respective machining requirements.

Construction 9

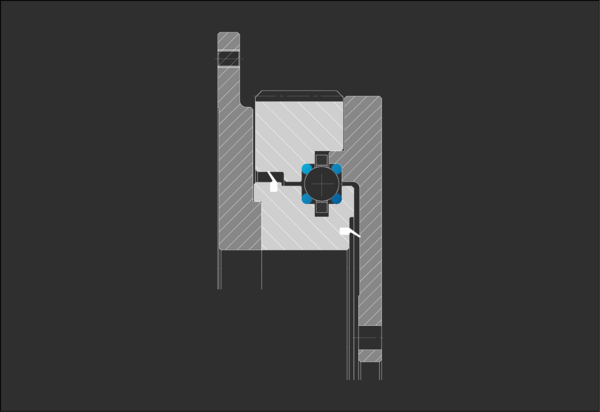

4-point ball bearing

To ensure the reliable operation of satellite antennas on ships, the bearing must be able to withstand extreme conditions. Our customized slewing ring ensures high rigidity over the entire service life in order to safely absorb shock loads caused by heavy swell. Thanks to a specially developed steel variant with a threaded ring, the bearing offers excellent corrosion resistance as well as constant rotational resistance - even at temperatures from -25 °C to +60 °C. An additional running-in process and the option of readjustment ensure the permanent functionality and stability of the bearing so that the antenna remains precisely aligned at all times.

Construction 10

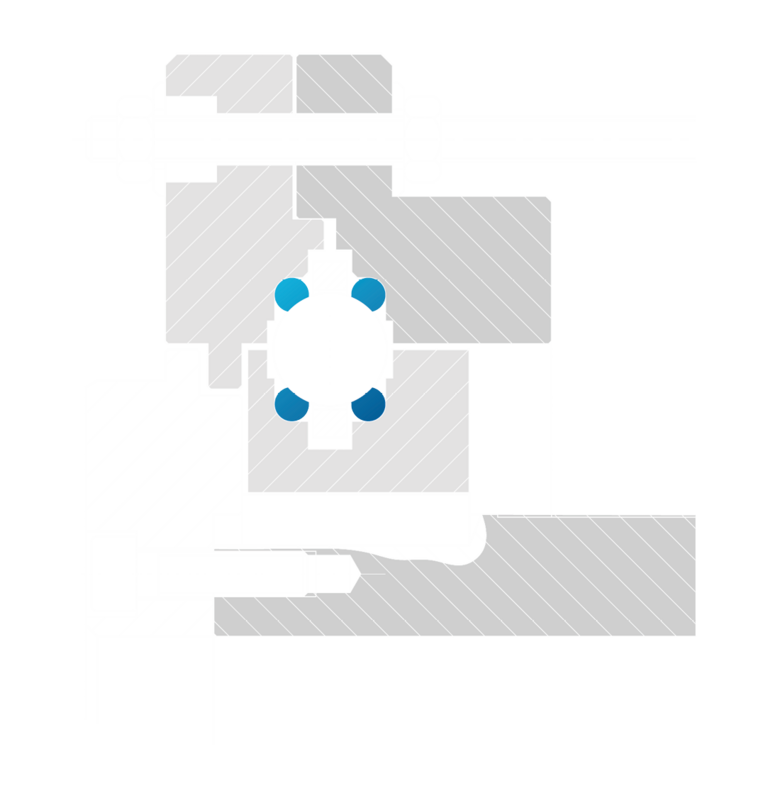

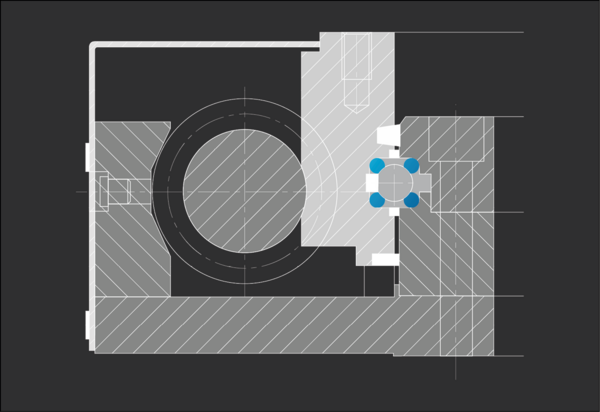

4-point ball bearing

An absolutely low-noise roller bearing is required for the fan of a domestic ventilator. The bearing must not only ensure minimal running noise, but also compensate for manufacturing tolerances of the injection-molded housing. As the housing has a compact design, only limited installation space is available. To further reduce noise, the ball cage of the roller bearing is only fitted with every second ball. The injection-moulded housing has also been optimized to make series assembly easier for the customer. The bearing seat is precisely adjusted using a threaded ring.

Construction 11

4-point ball bearing

The roller bearing used in the rotary indexing table must ensure smooth, jerk-free and shock-free movement of the rotary tables. At the same time, high repeatability and positioning accuracy are required in the end positions, even with high payloads.

Franke wire race bearings are optimally matched to the different loads and ensure the desired smooth running. Thanks to the proven four-point system, they reliably support all loads that occur.

Construction 12

4-point ball bearing

The rolling bearings for laser optics in aircraft must offer maximum precision and high rigidity. Specially developed for use in aircraft protection, they must also effectively compensate for thermal expansion to ensure reliable performance. A custom-made slewing ring is used as a cylindrical roller bearing made of aluminum as well as an additional three-point bearing. The slewing ring achieves a concentricity and axial run-out accuracy of 0.03 mm. Thanks to the lightweight aluminum construction, a considerable weight reduction is achieved. The load ratings, rigidity and accuracy are determined by the precisely manufactured races. The three-point bearing has a bearing angle of 45°, while the movable outer ring optimally compensates for thermal expansion.

Construction 13

4-point ball bearing

The main bearing of a baggage scanner not only has to ensure smooth and even rotation at up to 150 rpm, but also accommodate other components such as slip rings, X-ray detectors and drive elements. In addition, low noise levels, a large center clearance and a maintenance-free, durable design with over 50 million revolutions are required. The solution is a slewing ring manufactured specifically for the application as a 4-point bearing made of aluminum with custom-designed housing rings. Thanks to its compact design and large center clearance, the bearing offers optimum integration into the system. The lightweight aluminum design also ensures a significant weight reduction.

Construction 14

4-point ball bearing

The main bearing of a baggage scanner not only has to ensure smooth and even rotation at up to 150 rpm, but also accommodate other components such as slip rings, X-ray detectors and drive elements. In addition, low noise levels, a large center clearance and a maintenance-free, durable design with over 50 million revolutions are required. The solution is a slewing ring manufactured specifically for the application as a 4-point bearing made of aluminum with custom-designed housing rings. Thanks to its compact design and large center clearance, the bearing offers optimum integration into the system. The lightweight aluminum design also ensures a significant weight reduction.

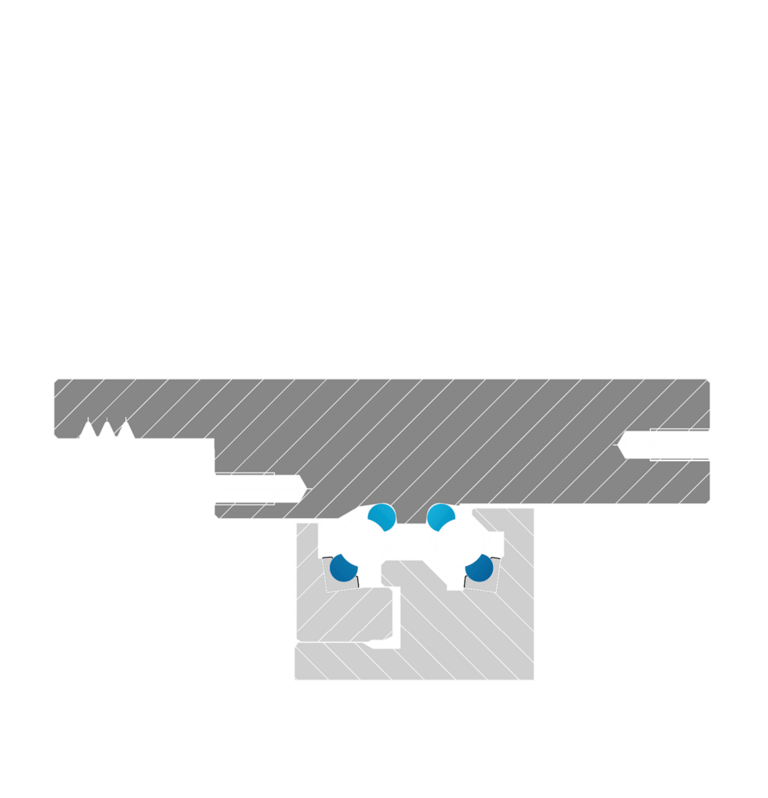

Construction 15

4-point ball bearing

The main bearing of a circular knitting machine makes a decisive contribution to the quality of the knitted fabric. Despite high mechanical and thermal loads, it must guarantee both maximum precision and a long service life.

A specially matched, ground wire race bearing made of chrome-silicon ensures smooth, quiet running with minimum space requirements. Its high axial and radial run-out accuracy (< 0.03 mm) and the excellent surface quality of the raceways guarantee the consistently high quality of the textiles produced. Depending on the machine type, the axial load from the machine cylinder is around 4,000 N.

Construction 16

4-point ball bearing

The rolling bearing for a mobile satellite antenna must not exceed a maximum total weight of 1 kg and must ensure smooth running and high tilting rigidity at the same time. The solution is a customer-specific, ready-to-install slewing ring made of aluminum with external gearing. Its compact design allows a large centerline clearance with minimal space requirements. The integrated toothed belt gearing ensures precise and reliable power transmission.

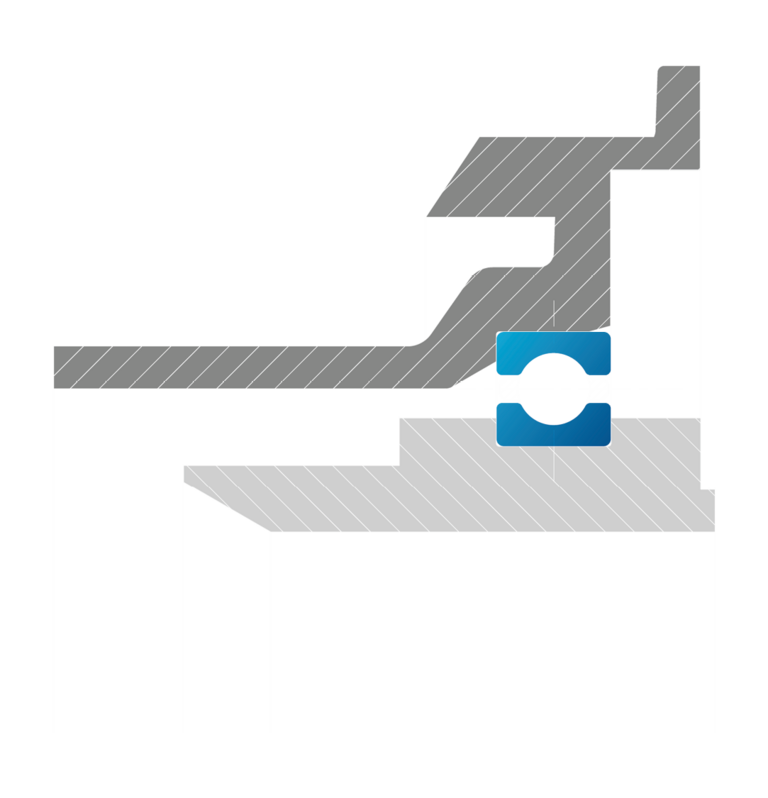

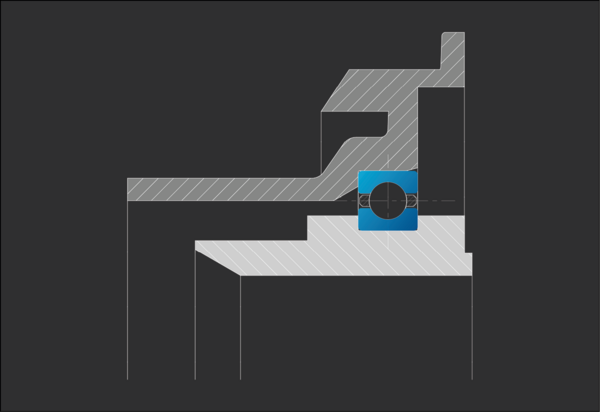

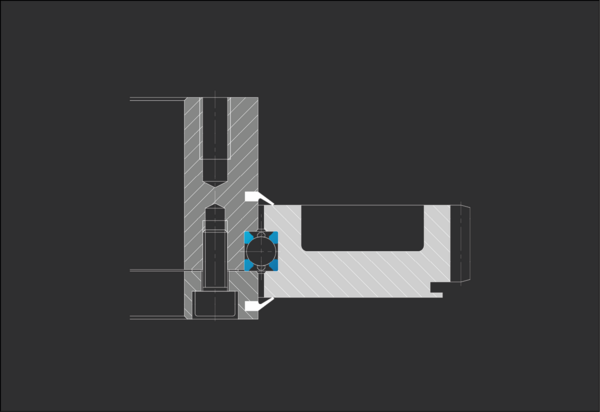

Construction 17

4-point ball bearing

In the tool changer of a machining center, a rolling bearing is used as a slewing ring to precisely feed the various tools to the machining head. High accuracy is essential to ensure safe and reliable tool changes.

Thanks to the large center clearance of Franke slewing rings, the entire drive system can be relocated inwards to save space. A combination of labyrinth and lip seals reliably protects the raceways from chips and coolant. The tool holders are attached directly to the outer ring.

The selected preload ensures high precision, uniform rotational resistance and therefore smooth, precise and long-lasting bearing movement.

Construction 18

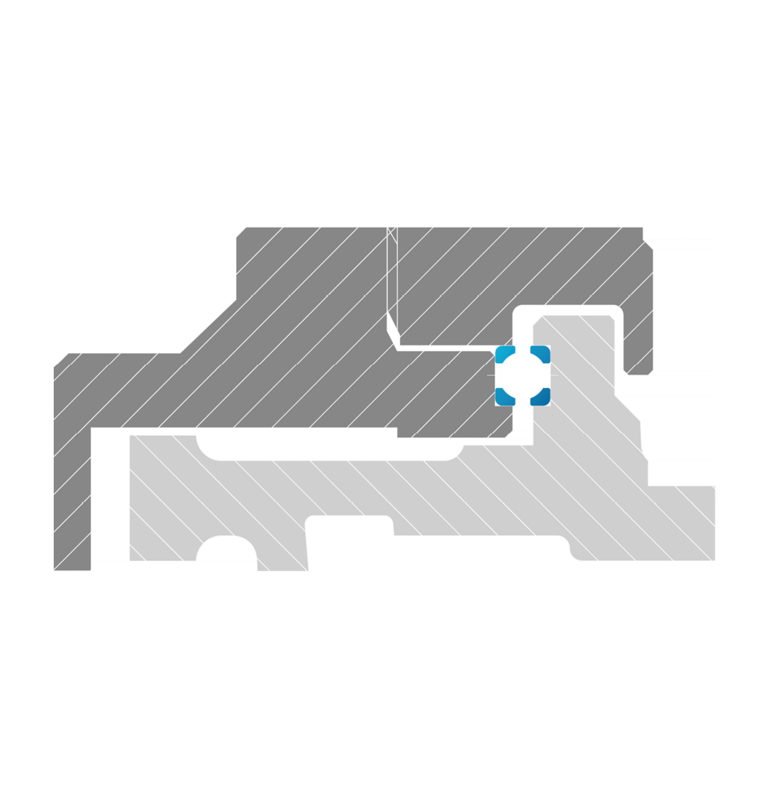

2-row angular contact ball bearing

As the hubless rim of a Formula Student electric racing car, the aluminum-carbon rim is intended to accommodate drive and braking devices in its center. The rolling bearing used must offer a large center clearance, require minimal installation space and at the same time safely transmit high forces and torques. Franke rolling bearings are integrated directly into the housing parts of the rim as double-row angular contact ball bearings. The wire race bearing reliably supports the loads that occur and works independently of the material of the surrounding construction. The compact design of the wires and rolling elements reduces the required installation space to a minimum. Thanks to the double-row angular contact ball bearing arrangement, the design enables highly dynamic motion sequences and ensures maximum performance with minimum weight.

Construction 19

4-point ball bearing

An innovative, lightweight and compact swivel joint for the precise adjustment and positioning of microscopes is integrated directly into the floor stand. The special requirements of the operating theater were taken into account when developing this solution.

A customer-specific swivel joint made of aluminum with a chemically nickel-plated surface is used. A spiral-shaped groove on the inside limits rotation to 540°, while spring tensioning elements prevent the microscope from swiveling uncontrollably. The preloaded bearing ensures backlash-free and rigid rotation.

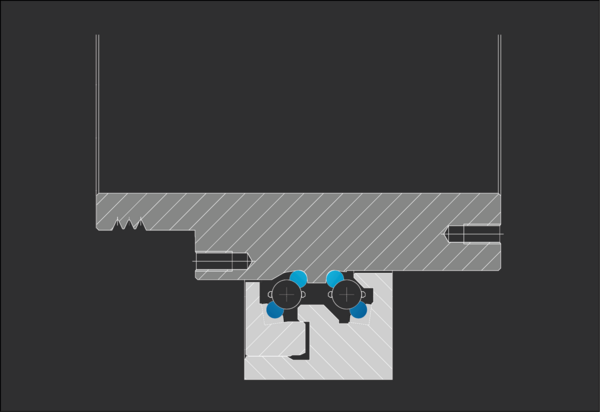

Construction 20

2-row angular contact ball bearing elastomer

The main bearing of the computer tomograph plays a decisive role in precise imaging. Even at high speeds, it must run quietly and with low vibration, while ensuring precise radial and axial run-out. The Franke slewing ring impresses with extremely smooth running at speeds of up to 300 rpm. An elastomer ensures effective noise reduction to 60 dBA. The bearing is also characterized by a low rotational resistance of less than 20 Nm and electrical insulation between the inner and outer ring.