Customer Stories

The great freedom of tube processing - with laser tube cutting machines from Trumpf

"Pipes choose Trumpf" is the title of an advertising brochure for Trumpf laser pipe cutting machines. The Swabian flagship company is a global leader in laser processing. Customer-specific wire race bearings from Franke are used in the chucks of its fully automatic cutting artists.

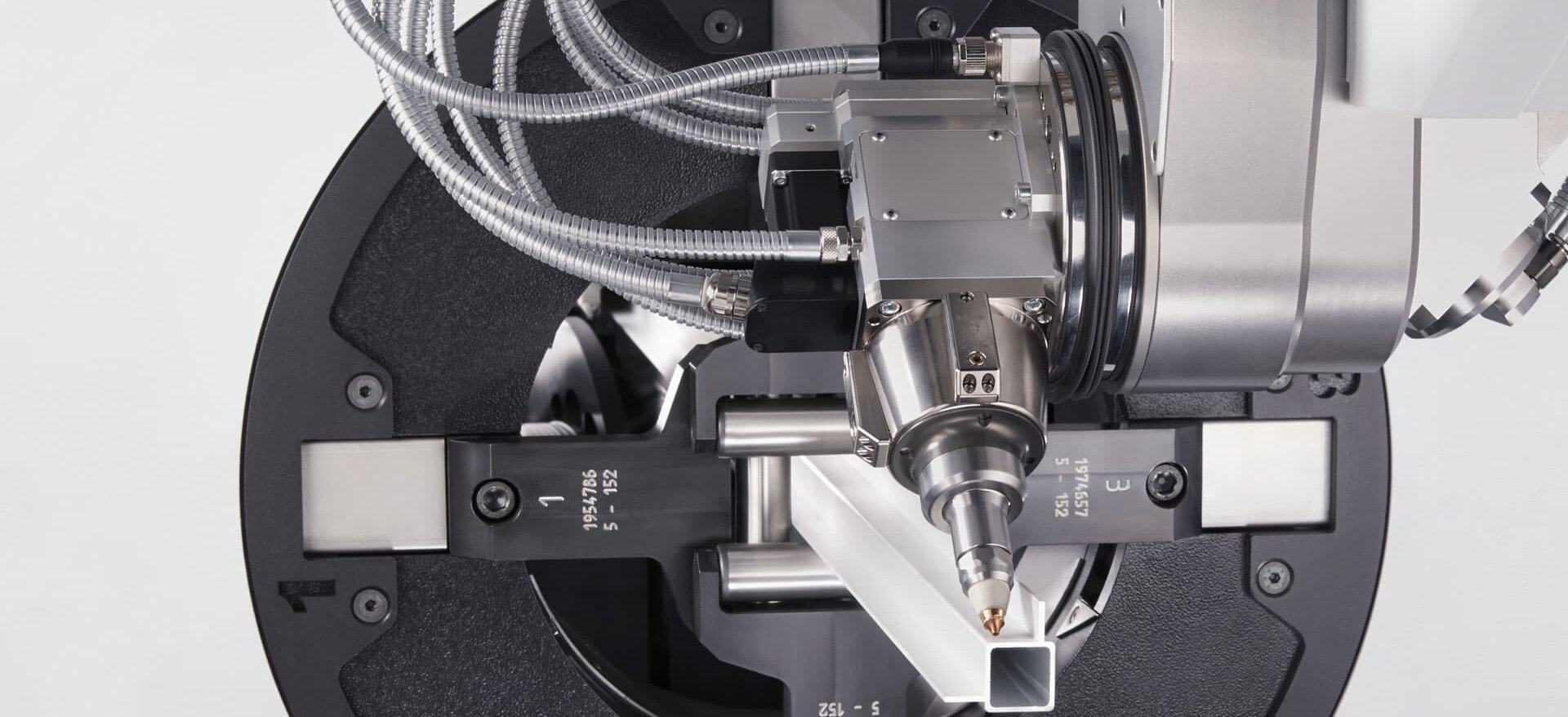

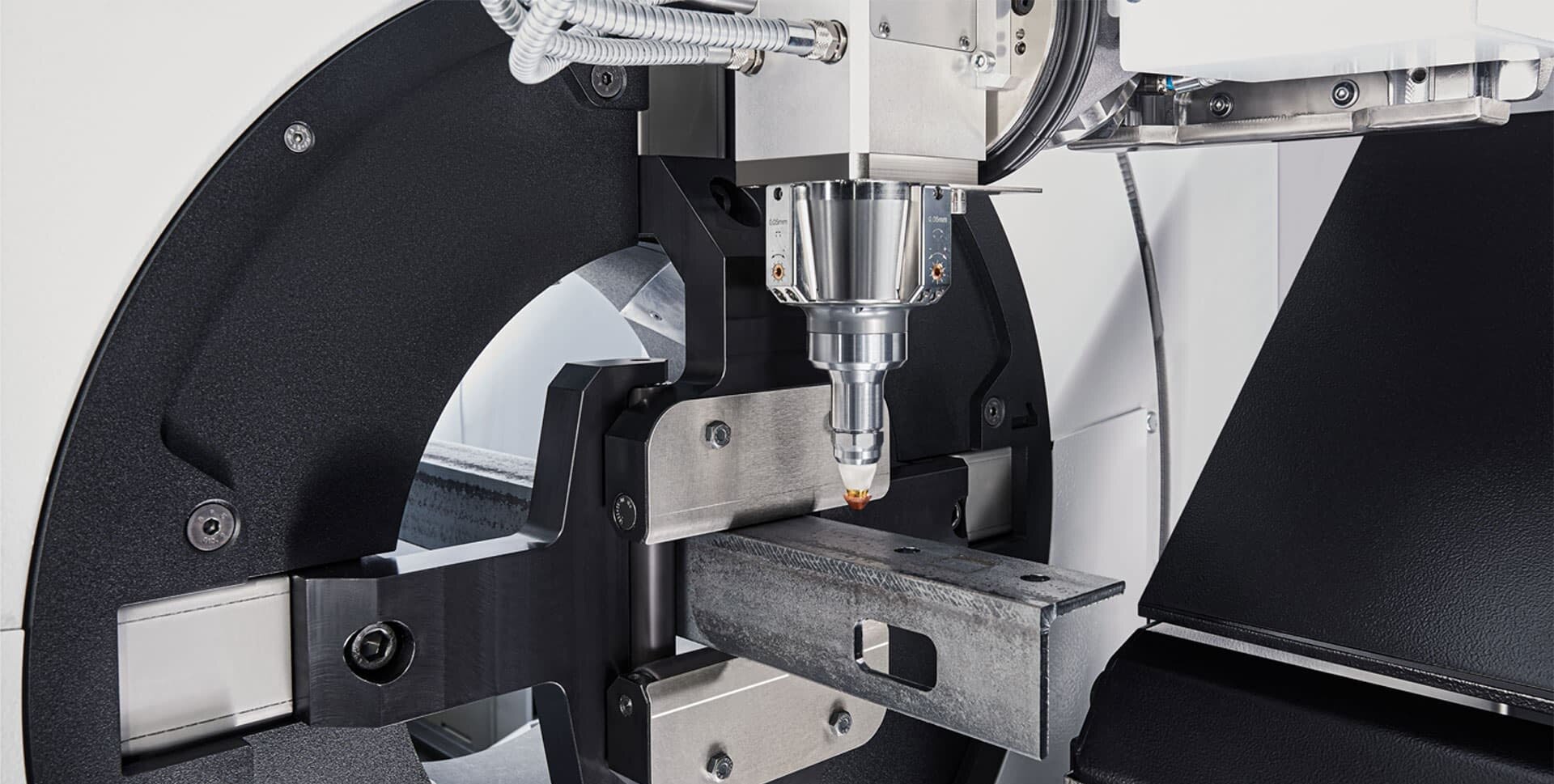

Even if the name suggests it: A Trumpf TruLaser Tube laser tube cutting machine is not limited to tubes. Almost all elongated hollow bodies and profiles made of metal with a wall thickness of up to 10 mm can be processed with this type of machine. We encounter tubes and profiles cut with it at every turn: in bicycle frames, in designer lamps, in the form of grab rails in trains and subways. Often, laser-cut profiles are also used in a hidden way, for example in frame constructions of vehicles and machines.

Cutting free forms - in one go

A weighty argument in favour of shaping tubes with a laser is the freedom of shape design. Unlike a saw, a Trumpf TruLaser Tube, for example, can not only make straight cuts, but can also cut any free form. Extended by a threading unit, the machine even forms threads. Instead of sawing, drilling and milling in several steps with several machines, the Trumpf machine takes over the entire processing fully automatically in one go. And it does it so cleanly that deburring is no longer necessary.

Profile of the Franke solution

Customised Franke bearing assembly with double bearing

Bearing requirement: Precision and reliability

Special challenge: Short delivery times and the availability of Franke bearings must always be guaranteed

Simplifying subsequent processes - for more productivity

The laser tube cutting machine provides an additional boost to overall productivity because it can significantly simplify subsequent processes. Thanks to clever designs, laser-cut components can be easily bent, kinked, aligned or plugged together. This is much faster than the time-consuming positioning and welding of individual parts. The components required for this, which often have complex shapes, can be manufactured highly productively and with high precision using a Trumpf machine.

Examples of innovative laser-cut components in the linked video: https://www.youtube.com/watch?v=Taz9LARGKYw

Growing demand for TruLaser Tube machines

The ease of realising such new design ideas is also a main reason for the growing demand for TruLaser Tube machines, reports Markus Stapf, Group Manager in Purchasing at Trumpf. The success of the machine type can also be seen in Franke's order volume. "The order volume with Trumpf has been growing continuously for years," says Heike Faustmann, who is responsible for handling the commercial processes with Trumpf at Franke.

The good thing about the Franke product: it works.Markus Stapf, Group Manager in Purchasing at Trumpf

Innovative clamping with Franke bearings

A laser tube cutting machine from Trumpf is a high-tech product packed with innovative ideas. This also includes the clamping technology. It is designed in such a way that the time required for set-up is reduced to zero and tedious reclamping is eliminated. The two chucks of a TruLaser Tube machine are fitted with customised double bearings from Franke. "The chucks are central components of our machines," says development engineer Holger Biener. "They have to ensure that the component is positioned exactly. This is the only way to ensure accurate machining." In this context, the Franke double bearings fulfil an elementary function, because any inaccuracy in the bearing would immediately affect the accuracy of the machining. In addition, high reliability is required of the bearing. They are very satisfied with Franke bearings in this respect, reports Markus Stapf: "The good thing about the Franke product: It works - we have no problems at all during assembly or in the field."

Actually, we only wanted to buy standard bearings from Franke.Holger Biener, Trumpf development engineer

Customised bearing assemblies instead of standard bearing elements

The chucks in a TruLaser Tube are a Trumpf in-house design and they are also manufactured by Trumpf. "Actually, we only wanted to purchase standard bearings from Franke," recalls development engineer Holger Biener. But Christian Burghard from Franke's technical sales department convinced them of an extended solution in the form of a customised bearing assembly. This is supplied as a compact, closed unit, which considerably reduces the assembly effort. Trumpf receives a perfectly matched, ready-made solution from the rolling bearing specialist Franke. "We can tick that off, we don't have to worry about it any more," says Holger Biener. He considers Franke's suggestions on this and the joint search for a good solution to be very positive.

Success factors for a good business relationship

Markus Stapf emphasises that product quality is not the only decisive factor for a successful business relationship with Franke. "We generally require very open communication, transparent processes and also transparent prices from our suppliers." Depending on the economic situation, flexible support is required and Franke has "succeeded very well in this in recent years." For example, good solutions have been found to better align the production systems with each other. This is necessary, he says, because fast availability is becoming increasingly important worldwide, but especially in Asia.

Franke contact Christian Burghard is proud to have found answers to Trumpf's requirements with Franke: "We have already achieved significant improvements with the new processes we have introduced, and we are continuing to work on optimally fulfilling the expectations placed on us."

Profile of the Franke solution

Customised Franke bearing assembly with double bearing

Bearing requirement: Precision and reliability

Special challenge: Short delivery times and the availability of Franke bearings must always be guaranteed

About Trumpf

The high-tech company Trumpf offers manufacturing solutions in the fields of machine tools and laser technology. Trumpf is driving digital networking through consulting, platform and software offerings. The company is the technology and market leader in machine tools for flexible sheet metal processing and in industrial lasers. In 2019/20, Trumpf generated sales of 3.5 billion euros with around 14,300 employees. With more than 70 subsidiaries, the Trumpf Group is represented in Europe, North and South America and Asia.