Customer Stories

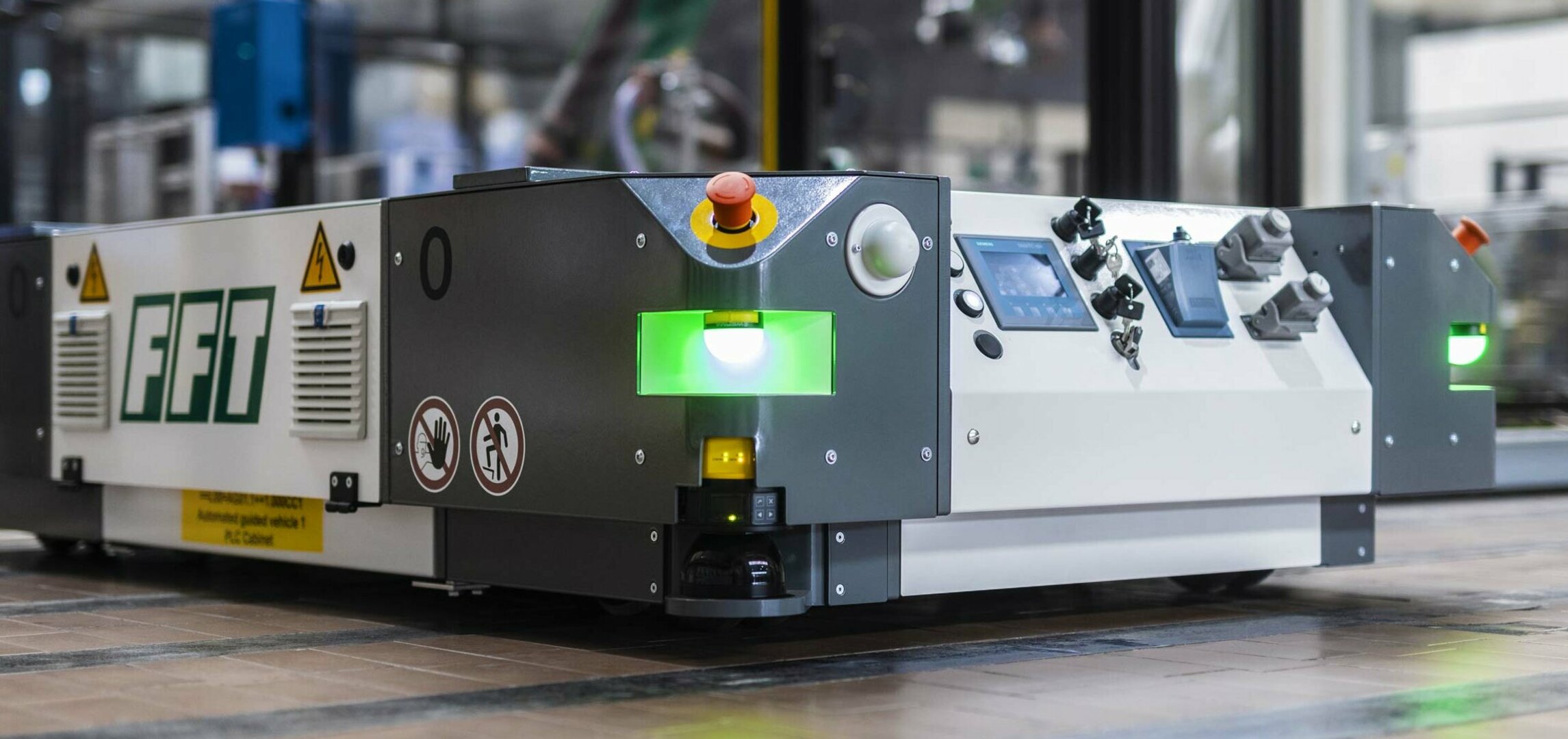

Automated guided vehicles from the global production optimiser

Always thinking one step ahead and offering flexibility - that is the credo of FFT, a leading global provider of automated manufacturing solutions. To achieve this, the plant manufacturer relies on collaboration between humans and robots and on digital networking. As automated guided vehicles are also frequently required in FFT's projects, the company began to manufacture these itself and sell them as independent products. Franke bearing assemblies are installed in the FFTigv AGILITY product variant.

FFT is a supplier of complex production systems and a manufacturer of its own system components for joining, folding and separating, for image-supported processes, and for handling and transport tasks. As a system provider, however, FFT is not limited to its own products. For example, FFT purchases robots and many other components from other manufacturers.

Franke is the inventor and manufacturer of wire race bearings. Wire race bearings can be integrated directly into the enclosing structure. Franke bearing assemblies can be customized to the customer's requirements. They are available in any size, with individual bores and toothing and in numerous materials such as aluminium, stainless steel, carbon or as a 3D-printed housing.

Automated guided vehicles as a separate product category

In order to link several system components together logistically, FFT requires, among other things, automated guided vehicles (AGVs). These can be fully automated on one hand, and can be used very flexibly on the other. Even if production processes and transport routes change, the self-propelled vehicles can be adapted to the new situation with relatively little effort.

Such self-propelled vehicles were required for FFT's plant projects in China and Vietnam in 2021. "As FFT, we jointly decided to develop and manufacture these ourselves in order to subsequently turn them into a separate product category," reports Account Manager Christian Schuster, who is responsible for sales of driverless transport systems. Already installed in 2021: bearing assemblies from Franke.

Profile of the Franke bearing assembly used:

Franke bearing assemblies of the type LVA 350

Advantages utilized: Variety of variants, compactness, durability

The size of the installed components plays a decisive role in the development of the overall system.Nils Kramm, design engineer at FFT

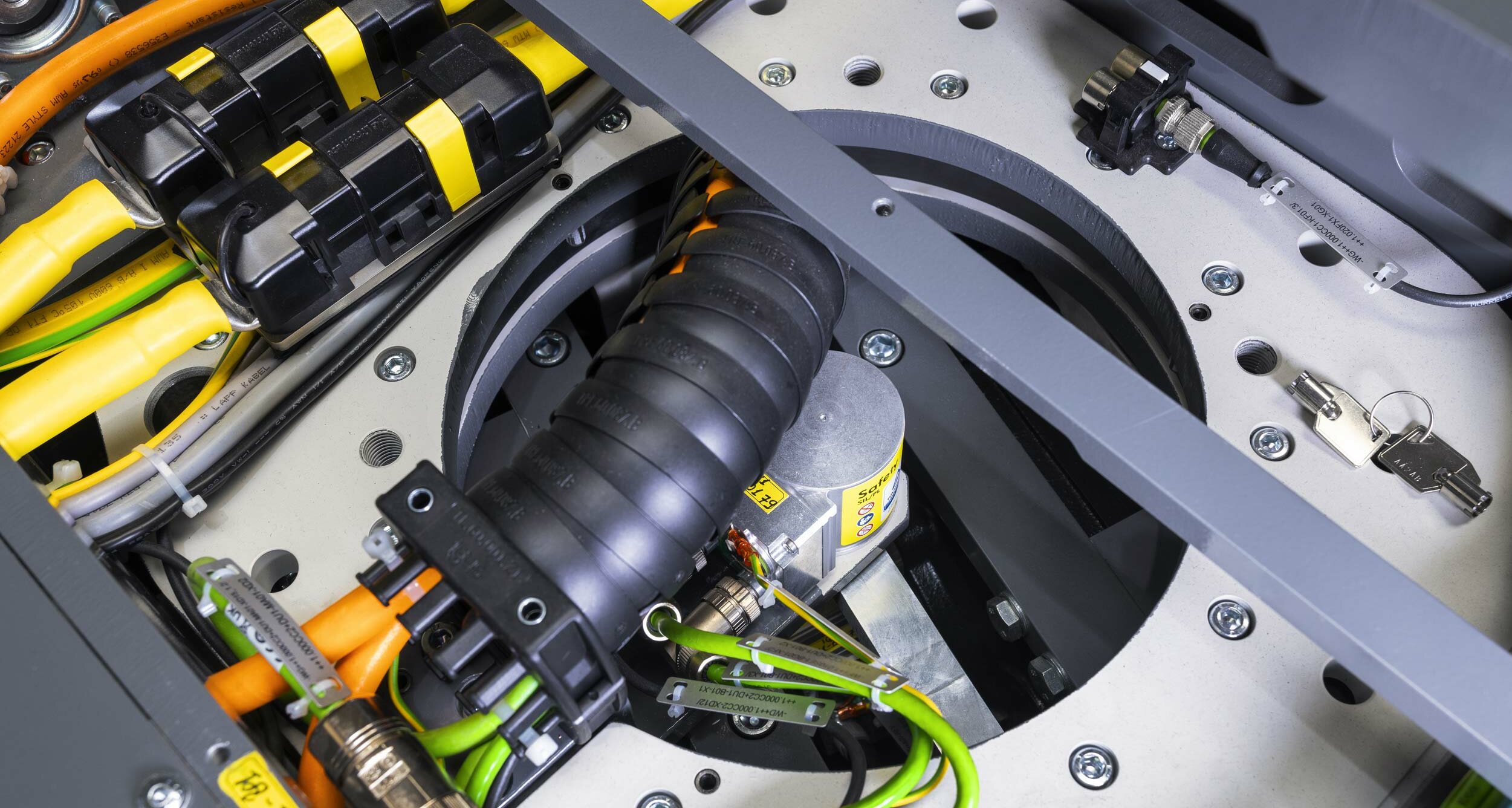

Exactly the right size of bearing

Nils Kramm, responsible for the mechanical design of the transport systems, was already familiar with Franke technology from a previous job and from a research project with the Fraunhofer Institute. He and his colleagues opted for a practical ready-to-use solution from Franke to steer the driverless transport systems: bearing assemblies from the LVA series. In terms of size, Franke had exactly the right product in its program: "The size of the installed components plays a decisive role in the development of the overall system," explains Kramm.

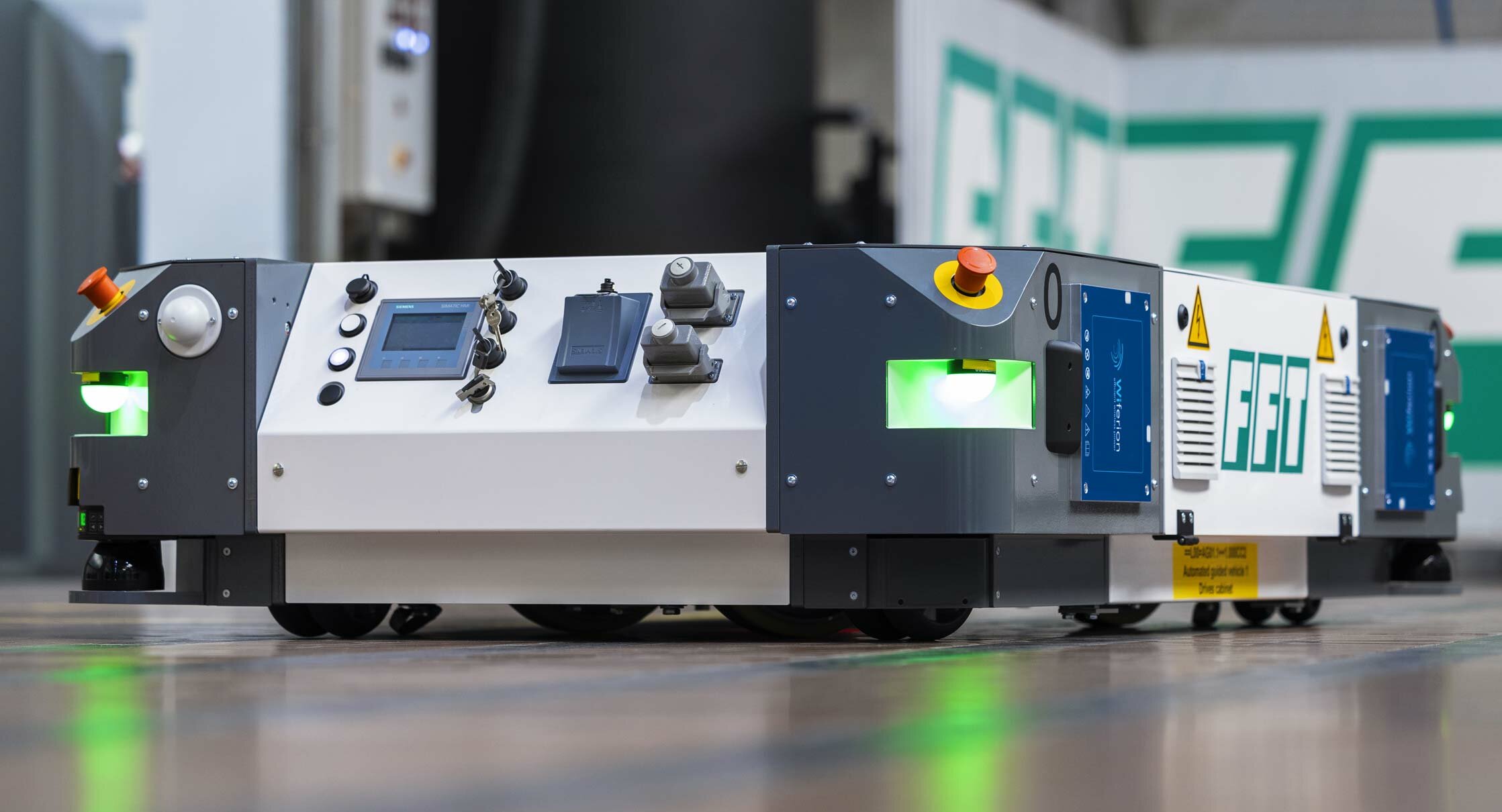

Franke bearing assemblies for the agile product variant with lifting unit

Using the experience gained with its first driverless transport system, FFT has since developed the product further, and will continue to optimize it in the future. Franke bearing assemblies type LVA 350 are currently installed in the highest expansion stage of the transport system called FFTigv AGILITY. This comprises two drive units, each with a Franke bearing assembly for steering. The two wheels of a drive unit are driven and controlled individually. The FFTigv AGILITY is very agile when travelling with this drive: it can turn on the spot, drive crossways and turn at almost right angles. The equipment also includes a lift unit with a 150 mm stroke.

Process integration as a USP

The FFTigv AGILITY impresses with its product quality and functionality. "However, our greatest competitive advantage is our expertise in integrating the transport system into the customer's automated processes," explains Account Manager Christian Schuster. "It takes more than just driving from A to B. The vehicles also need to be loaded and unloaded automatically. We fully cover the associated interface issues". Flexible customization is one of FFT's particular strengths. This is reflected in the fact that FFT's transport systems are preferably fitted with industry-standard components. "This makes maintenance and subsequent adjustments to the process easier for customers. Customers don't buy a black box from us," explains Christian Schuster.

The FFTigv AGILITY is currently available with a load capacity of 1.5 and 3 tonnes. A further variant with a load capacity of 10 tons is in planning. "We can realize this by scaling the number of drive units, among other things," explains mechanics developer Nils Kramm. Four Franke bearing assemblies would then be installed in this variant.

Technically, the bearing assemblies fit our requirements perfectlyNils Kramm, design engineer at FFT

Direct contact with Franke

Nils Kramm has had good experiences with Franke products and the collaboration with Franke: "Technically, the bearing assemblies fit our requirements perfectly. We maintain close contact with Franke via Franke consultant Andreas Böttcher. We received valuable support by telephone and directly on site when it came to the technical design of the bearing assemblies and project planning with regard to economic issues."

About FFT

FFT is a leading global supplier of complex manufacturing systems with headquarters in Fulda. FFT assumes overall responsibility for the development, project planning and realization of complex manufacturing systems through to turnkey delivery. FFT systems are mainly used in the automotive and aviation industries, but also in other sectors, for example in the production of white goods. FFT was founded in 1974 in Mücke, Hesse. In 2022, the company employed almost 2,900 people and generated a turnover of over 670 million Euros.

Profile of FFT

Head office: Fulda

Founded: 1974

Expertise: Complex and flexible manufacturing systems as turnkey solutions

Website: www.fft.de