Exemple d'application Cleaning of a dosing unit

Requirements

Screw feeders, which are positioned above the bag machine during production, are to be swiveled by 90° for cleaning and then moved downwards by approx. 1 m. It is important to absorb the short-term rotational tilting moments that occur. The linear movement required for the process must be smooth and jerk-free. The available space is very limited. In general, the components used must meet the hygiene requirements in the food processing sector.

Solution

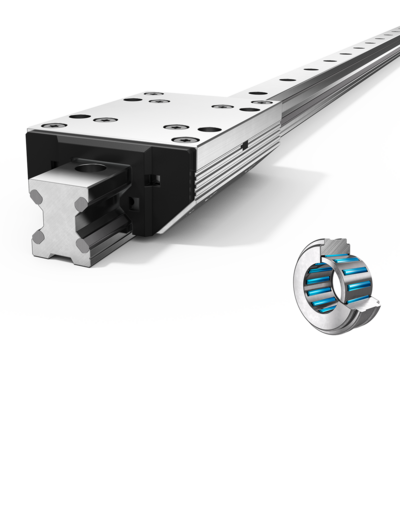

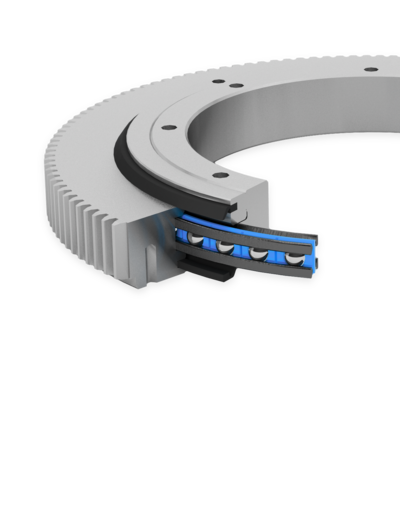

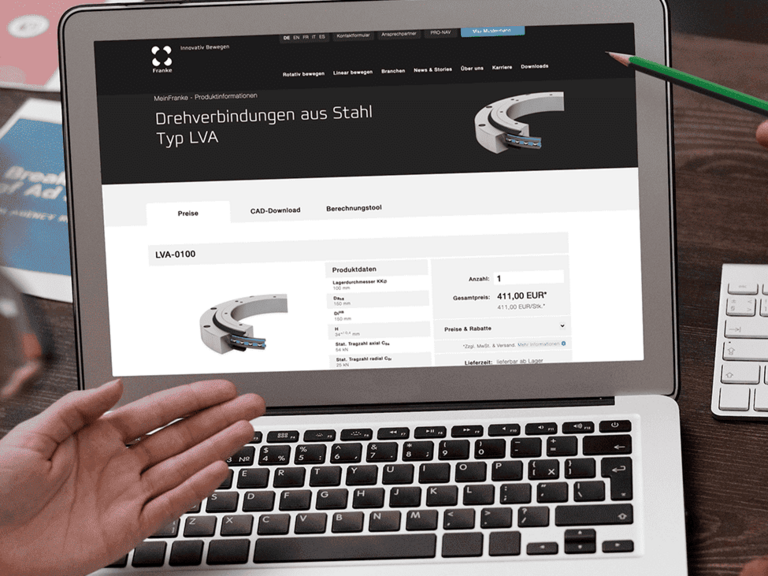

A preloaded slewing ring type LVD-0300 with external gearing, which is driven by a soft pinion, is used for rotation. The stroke movement takes place via a Franke linear guide FDA45 in which the wipers are impregnated with food oil.

Bearing solution used

Result

Reliable and process-safe swivel movement at 3 rpm with a long expected service life. By combining rotary and linear components, it was possible to develop a compact unit that can be optimally integrated into confined spaces.